Inconsistent steel isn't a supply issue—it's a multi-crore production risk. Since 1969, India’s leading engineering firms have relied on Marbrite Steel for one reason: certainty. With a 78% repeat customer rate, our clients don't just buy precision bright bars; they buy the guarantee that their machinery, their components, and their reputation will not be compromised.

Stop letting inconsistent steel dictate your production schedule. Our EN8D & EN9 grades are sourced from verified mills with full traceability, guaranteeing the precise chemistry and hardenability needed for reliable, uninterrupted machining.

Your consistency starts with ours.

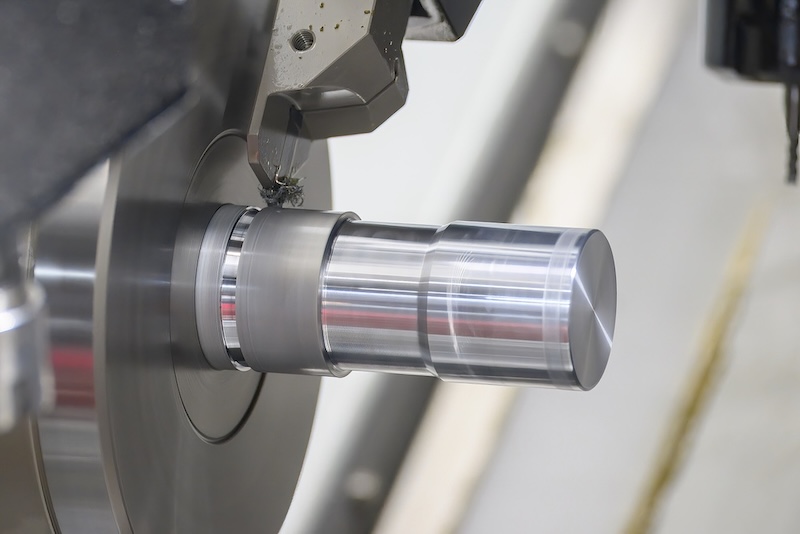

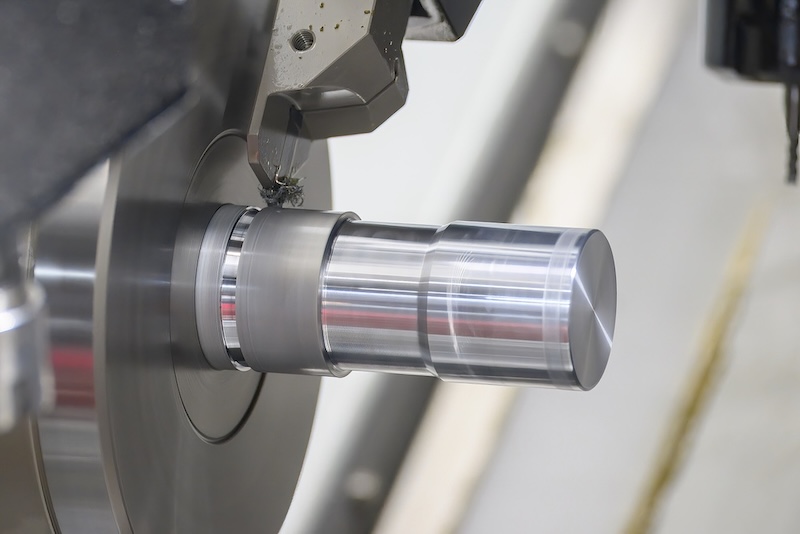

Traceable alloy steel is just potential until it's processed. Our precision cold drawing transforms high-grade SAE 4140 & EN24, creating a bar with superior dimensional accuracy and a highly refined surface finish. This meticulous work improves the steel's strength and material integrity, giving your most critical components the reliability they need to perform under pressure.

Don't just buy steel; invest in processed certainty.

Every rotation tests the limits of your steel. Our EN31 & SAE52100 are engineered for maximum endurance. Its high-carbon chemistry provides the superior wear resistance and surface hardness needed to withstand constant stress and abrasion, drastically extending component life.

Build for endurance, not for replacement.

A brittle core can shatter a gear and your customer's trust along with it. Our 8620 & 20MnCr5 grades are engineered to prevent this, creating the crucial fusion of a hard, wear-resistant surface and a tough, ductile core.

It's the resilience your reputation is built on.

Every minute your machine spends on setup adjustments is a loss you can never recover. We deliver ground bars engineered to eliminate that waste. With an exacting surface finish and dimensional control ready for immediate machining, our bars slash setup times and maximize your throughput. Don't just buy steel; buy back your machine time.

Don't let hidden liabilities in your raw material compromise your final product. Our peeling process removes all surface imperfections, eliminating the risk of subsurface defects appearing mid-production. We deliver the flawless foundation your components demand.