JIS SCM420 Case Hardening Steel

The Japanese Standard for Precision Gearing.

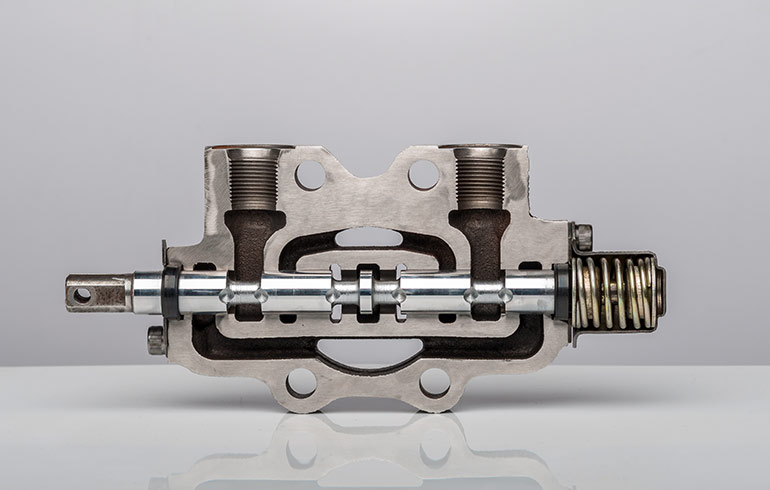

Precision machinery demands precision materials. For high-performance gears and drivetrains that operate under constant stress, there is no room for compromise. JIS SCM420 is the Japanese standard for this demanding application—a chromium-molybdenum case hardening steel engineered for a flawless response to heat treatment. It provides the ideal combination of a hard, wear-resistant surface and a tough, resilient core, ensuring reliability where performance is paramount.

The Balance of Power and Resilience

High Surface Hardness

Achieves a very hard surface case (over 60 HRC) after carburizing, providing exceptional wear resistance.

Superior Core Toughness

The chromoly chemistry ensures the low-carbon core remains ductile and tough to absorb shock and impact.

Excellent Wear Resistance

The hard-wearing case is ideal for the metal-on-metal contact found in high-performance drivetrains.

A Clean Steel Foundation

Manufactured to high standards of purity to ensure a long fatigue life and reliable performance under load.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.18 - 0.23 |

| Chromium (Cr) | 0.90 - 1.20 |

| Molybdenum (Mo) | 0.15 - 0.30 |

| Manganese (Mn) | 0.60 - 0.90 |

| Silicon (Si) | 0.15 - 0.35 |

Mechanical Properties (Core properties after hardening, indicative only)

| Property | Value |

|---|---|

| Surface Hardness (Case) | Up to 62 HRC |

| Tensile Strength (Core) | 930 - 1230 MPa |

| Yield Strength (Core) | ~785 MPa |

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| AISI / SAE | 4120 |

| BS | 708M20 |

Similar & Alternative Grades:

SCM420 is the Japanese JIS standard for this class of steel, often compared to its SAE equivalent, 4120.

Frequently Asked Questions about SCM420

What does SCM stand for?

SCM is a designation from the JIS (Japanese Industrial Standards). The 'SCM' prefix stands for **Steel-Chromium-Molybdenum**, indicating that it is a chromium-molybdenum alloy steel.

How does SCM420 compare to SAE 8620?

Both are excellent chromium-molybdenum case hardening steels. The main chemical difference is that SAE 8620 also contains Nickel, which can provide slightly superior core toughness for the most extreme shock loads. They are often used in similar high-performance applications, with the choice depending on the specific OEM requirements.

Can you weld SCM420?

Due to its low carbon content, an SCM420 **bright bar** has good weldability **before** it undergoes any case hardening treatment. Welding after carburizing is not recommended as it will destroy the hardened case and compromise the component's integrity.

Precision Forged in Steel

The performance of a complex drivetrain is only as reliable as its most basic component: the gear. The Marbrite Standard for SCM420 is our commitment to providing a metallurgically clean and consistent foundation for your most precise work. We deliver **SCM420 round bars** that respond predictably to your heat treatment, allowing you to create components with the perfect synergy of a hard-wearing surface and a shock-absorbing core. Build with the precision the standard demands.