SAE 1541 High-Manganese Steel

The Smart Choice for Enhanced Toughness.

When the demands on a component exceed the limits of standard carbon steel, the solution isn't always a complex alloy. Often, the answer lies in a smarter chemistry. SAE 1541 is that intelligent solution—a medium-carbon steel fortified with a higher manganese content. This crucial addition provides a significant boost in hardenability and toughness, making 1541 the ideal choice for forged and machined parts that require a higher tier of strength and resilience.

The Power of Manganese

Superior Strength & Toughness

Delivers significantly higher strength and impact resistance compared to standard 1045 / C45 grades.

Increased Hardenability

The high manganese content allows for deeper and more uniform hardening during heat treatment.

Good Wear Resistance

Offers improved resistance to abrasive wear, making it suitable for moderately high-wear applications.

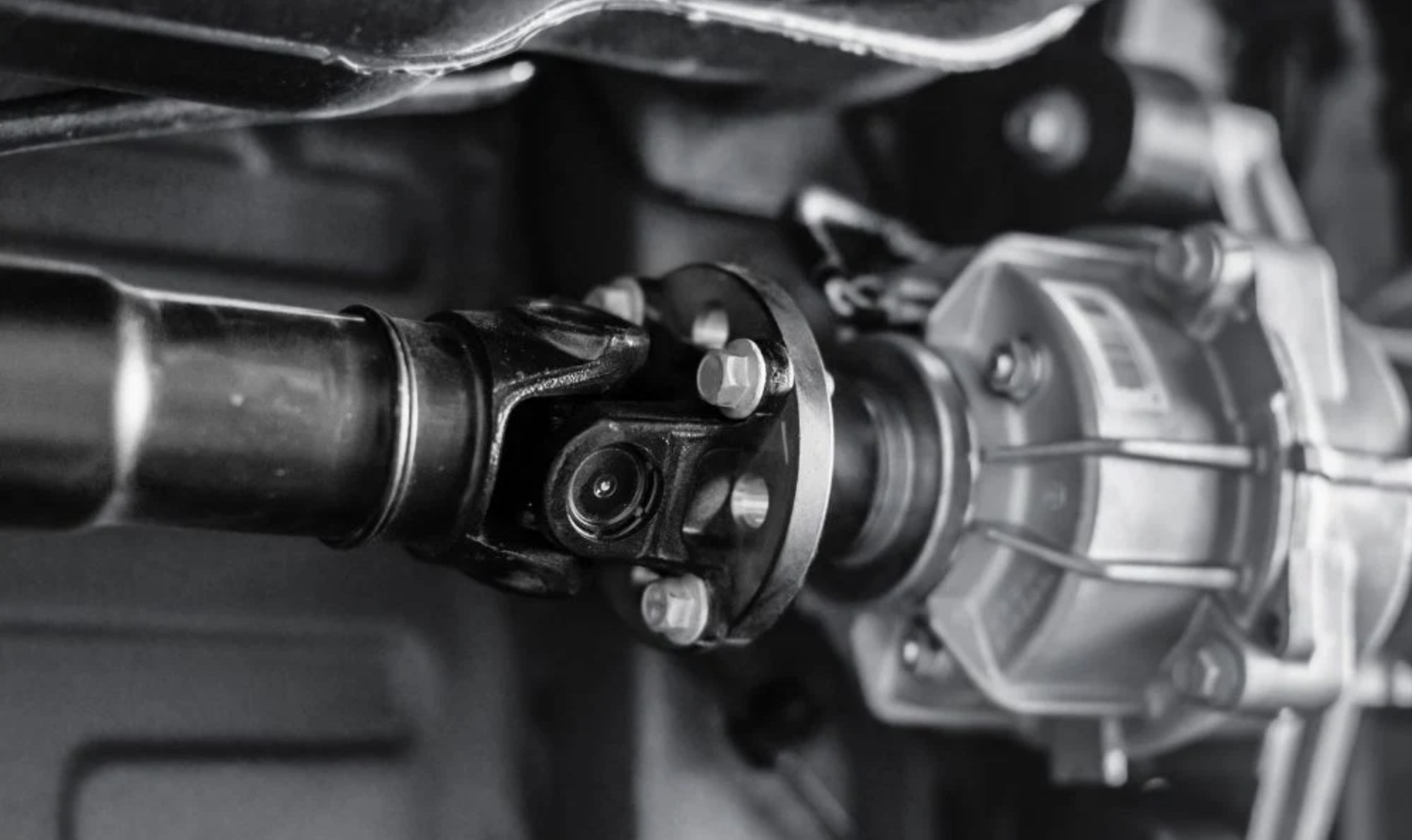

Excellent for Forging

Its robust properties make it a preferred grade for forged components like crankshafts and connecting rods.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.36 - 0.44 |

| Manganese (Mn) | 1.35 - 1.65 |

| Phosphorus (P) | 0.040 Max |

| Sulphur (S) | 0.035 Max |

Mechanical Properties (Hot Rolled, indicative only)

| Property | Value |

|---|---|

| Tensile Strength (MPa) | ~690 |

| Yield Strength (MPa) | ~380 |

| Hardness (Brinell) | ~201 HB |

Common Applications

Similar & Alternative Grades:

Also comparable to other international high-manganese grades such as DIN 40Mn4.

Frequently Asked Questions about SAE 1541

What is the main advantage of 1541 over 1045 (C45) steel?

The primary advantage is the significantly higher manganese content in an SAE 1541 round bar. This acts as an alloying agent to dramatically improve the steel's hardenability—its ability to achieve deeper and more uniform hardness after quenching. This results in a tougher and stronger final component compared to 1045.

Is SAE 1541 considered an alloy steel?

By chemistry, it is technically a high-manganese carbon steel. However, in terms of performance, it effectively bridges the gap between plain carbon steels (like 1045) and more complex chromium-molybdenum alloy steels (like 4140), offering a cost-effective upgrade in strength and toughness.

Can you weld 1541 steel?

Welding 1541 is challenging due to its higher carbon and manganese content and is generally not recommended for critical applications. It requires careful pre-heating and post-weld stress relieving procedures to prevent cracking in the heat-affected zone.

The Intelligent Edge

Choosing the right material is about finding the intelligent edge—the perfect balance of performance and value. The Marbrite Standard for SAE 1541 is our guarantee of that balance. We deliver 1541 bright bars with a precisely controlled manganese content, ensuring you get the enhanced toughness and hardenability this grade is known for. It's the smart upgrade that provides a clear performance advantage for your critical components.