SAE 9254 Spring Steel

Engineered to Bend, but Never Break.

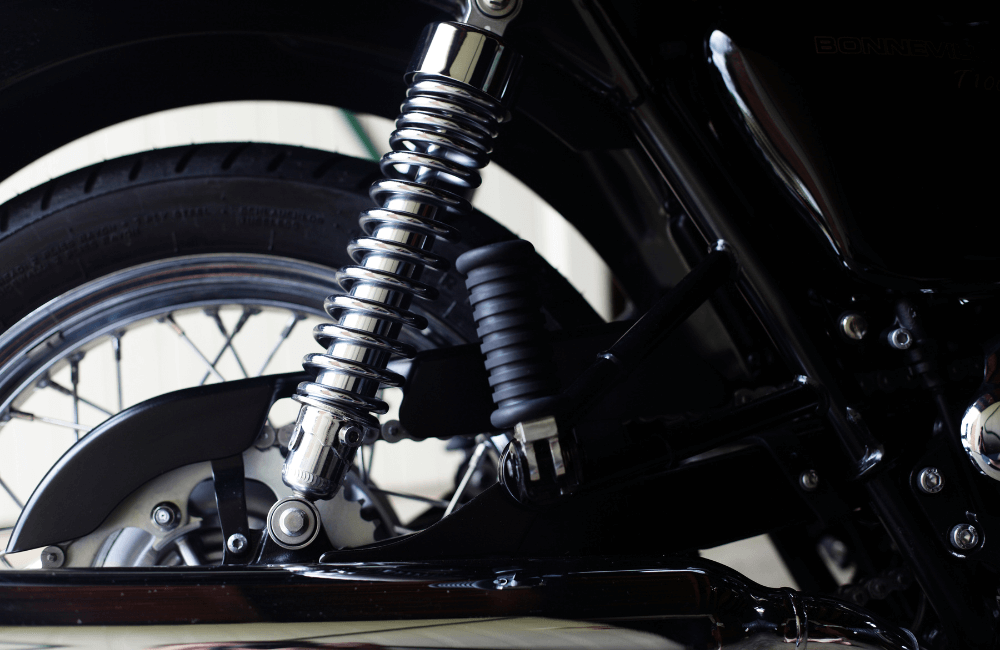

In the world of dynamic machinery, some components are not meant to be rigid; they are designed to absorb energy, to flex, and to return, time and time again. This is the art of resilience, and it requires a steel with a perfect memory. SAE 9254 is that steel—a high-performance silicon-chromium spring steel engineered for exceptional elasticity and the ability to endure countless cycles of stress without fatigue or permanent deformation.

The Art of Resilience

High Elastic Limit

The high silicon content allows the steel to bend significantly and return to its original shape without deforming.

Superior Fatigue Resistance

Engineered to withstand millions of flex cycles under load, preventing the cracks that lead to catastrophic failure.

Excellent Yield Strength

Possesses the high yield strength necessary to handle the stresses of energy storage and release.

The Perfect Spring Memory

Maintains its precise form and function through a lifetime of repeated use, ensuring consistent performance.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.51 - 0.59 |

| Silicon (Si) | 1.20 - 1.60 |

| Manganese (Mn) | 0.60 - 0.80 |

| Chromium (Cr) | 0.60 - 0.80 |

Mechanical Properties (Hardened and Tempered, indicative only)

| Property | Value |

|---|---|

| Tensile Strength (MPa) | ~1350 |

| Yield Strength (MPa) | ~1200 |

| Hardness (Rockwell C) | 45 - 50 HRC |

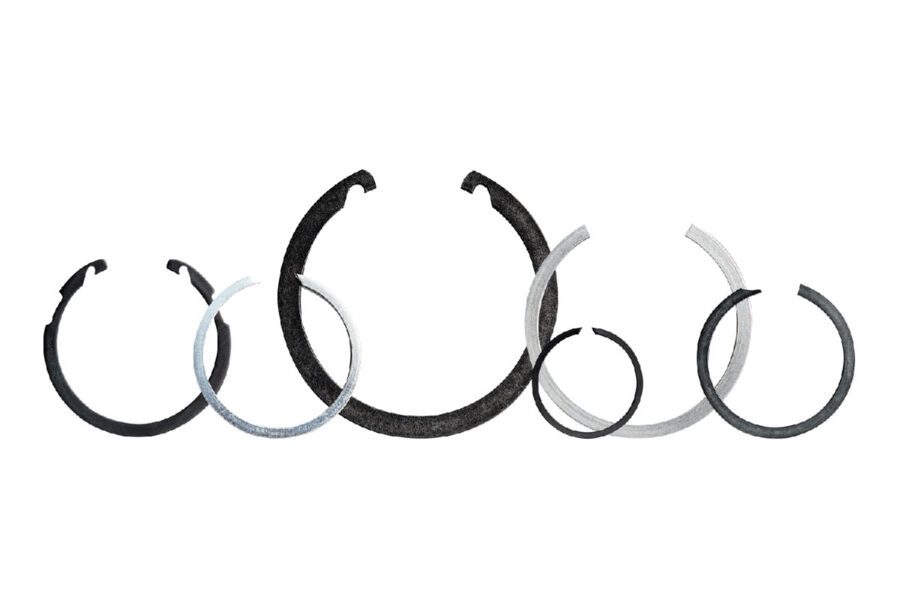

Common Applications

Similar & Alternative Grades:

Also comparable to other silicon-alloy spring steels such as EN45A and SUP7.

Frequently Asked Questions about SAE 9254

What makes 9254 a good "spring steel"?

Its high silicon content is the key. Silicon significantly raises the steel's elastic limit and resistance to permanent deformation (taking a set). This allows it to effectively store and release energy, which is the primary function of a spring, while the chromium adds strength and fatigue resistance.

How does 9254 differ from a standard alloy steel like 4140?

While both are strong, they are designed for different jobs. 9254 is engineered for **elasticity** and **fatigue life** under flexing loads. 4140 is engineered for **tensile strength** in rigid components. Using 4140 for a high-performance spring would likely result in it either breaking or permanently bending much sooner than 9254.

How is 9254 processed?

SAE 9254 is typically formed into its final spring shape (coiled, bent, etc.) in its softer, annealed state. After forming, the entire component is heat-treated (quenched and tempered) to achieve the high yield strength and resilience required for its spring properties.

The Memory of Steel

A spring's reliability is its memory—its unwavering ability to return to form after being subjected to immense stress. The Marbrite Standard for SAE 9254 is our commitment to a flawless chemistry. We deliver **9254 spring steel bars and wires** with the precise silicon and chromium content needed to create this perfect memory. Build with the resilience that allows your designs to endure, flex, and perform, cycle after cycle.