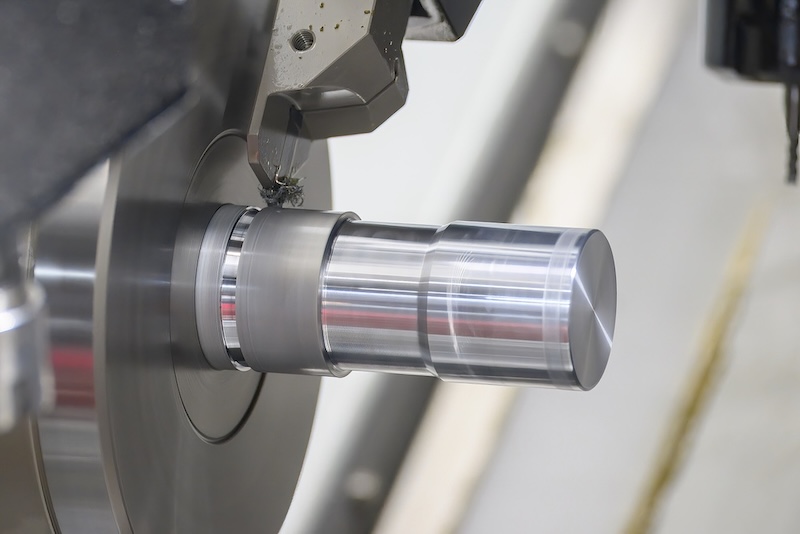

EN8M Free-Cutting Steel (212M36)

Engineered for the Speed of Production.

In manufacturing, time is the ultimate currency. Every second saved, every tool that lasts longer, and every component that comes off the machine with a perfect finish adds directly to the bottom line. Standard steels can be a bottleneck, holding your production hostage. EN8M is the solution—a free-cutting steel specifically engineered with controlled sulphur additions to shatter these limits. It is designed to liberate your machinery, enabling faster speeds, longer tool life, and a flawless finish.

The Production Multiplier

Superior Machining Speed

Engineered with sulphur to produce small, brittle chips that break away easily, allowing for significantly faster cutting speeds.

Maximize Your Tool Life

The free-cutting nature reduces friction and heat at the tool's edge, drastically reducing wear and replacement costs.

Achieve a Flawless Finish

The clean-breaking chips prevent surface damage, resulting in a superior surface finish directly from the machine.

Increase Production Throughput

Faster speeds and longer tool life combine to deliver a dramatic increase in your overall production efficiency.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.35 - 0.45 |

| Manganese (Mn) | 1.00 - 1.30 |

| Sulphur (S) | 0.12 - 0.20 |

| Silicon (Si) | 0.10 - 0.40 |

| Phosphorus (P) | 0.050 Max |

Mechanical Properties (in supplied condition, indicative only)

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 600 - 750 |

| Yield Strength (MPa) | ~430 |

| Hardness (Brinell) | 179 - 229 HB |

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| BS 970 | 212M36 |

| AISI / SAE | 1141, 1144 |

Similar & Alternative Grades:

Also comparable to its SAE free-machining equivalent, SAE 1141.

Frequently Asked Questions about EN8M

What does the 'M' in EN8M stand for?

'M' stands for Machining. It signifies that EN8M is a "free-cutting" or "free-machining" variant of EN8. It has been chemically modified, primarily with sulphur, to be significantly easier to machine at high speeds.

When should I choose EN8M instead of EN8D?

Choose EN8M when you are producing a high volume of complex, machined parts and your primary concerns are production speed, long tool life, and a superior surface finish. Choose EN8D when you need better toughness, impact resistance, and the option to weld the component.

Can EN8M be welded?

No. The same high sulphur content that makes EN8M excellent for machining is highly detrimental to welding, causing a condition called hot cracking. For this reason, EN8M is considered unweldable for any structural or critical application.

The Catalyst for Your Production

Your machinery is a significant investment, but its true value is only realized when it's running at peak efficiency. The Marbrite Standard for EN8M is our commitment to providing a free-cutting steel with a perfectly consistent chemistry and structure. We deliver EN8M bright bars that act as a catalyst for your entire operation—reducing cycle times, protecting your tooling, and allowing you to unlock a new level of productivity and profitability.