Precision Ground Bars

Where Failure is Measured in Microns.

Every microscopic deviation in your raw material is a seed of imperfection that grows through your entire manufacturing process. Precision grinding isn't a finishing touch; it's the foundational discipline that guarantees the geometric integrity of your work.

The Foundation of Zero-Defect Manufacturing

A flawless component cannot be built upon a flawed foundation. Every deviation in the raw material—no matter how microscopic—is a seed of imperfection that will grow through your entire manufacturing process. Precision grinding is not a final step; it is the first, most critical act of guaranteeing the geometric integrity of your work. It is the discipline of ensuring that the component you create is true, from its very core to its final form.

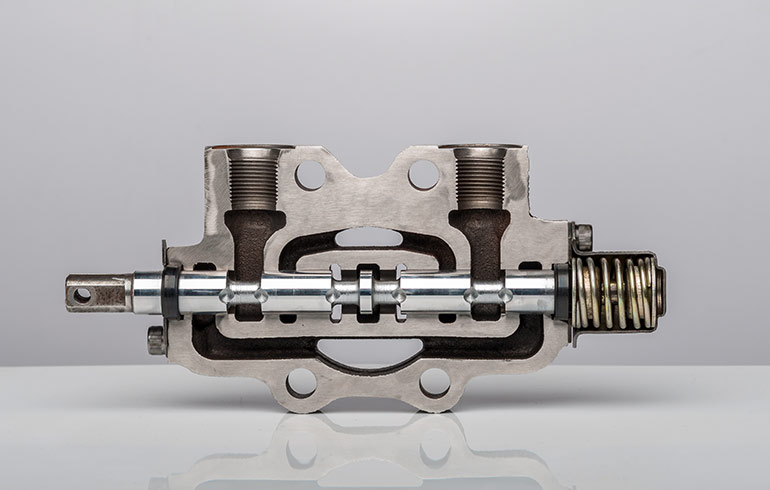

Meet Exacting Tolerances

We deliver bars to precise h-tolerances (h8, h9), ensuring perfect fit and function in automated assemblies.

Eliminate Finishing Steps

A superior surface finish (Ra value) reduces or eliminates the need for further costly polishing or finishing.

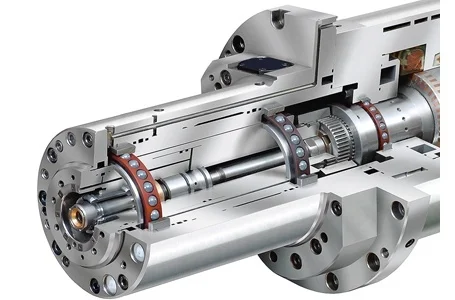

Ensure Perfect Rotation

Guaranteed roundness and concentricity for high-speed spindles and linear motion components.

Maximize Productivity

Our ready-to-machine bars prevent setup delays and protect your tooling from unpredictable material flaws.

Proven in Demanding Applications

The Marbrite Standard of Precision

For us, precision grinding is not a finishing service; it is a foundational discipline. The Marbrite Standard is our commitment to delivering absolute geometric integrity. We provide bars with a superior surface finish and the exacting dimensional control your automated processes demand. This is not about polish; it is about providing a foundation so perfect that it liberates your machines to do what they do best: produce, without compromise and without delay.