SAE 4140 Alloy Steel

Where Strength is a Prerequisite, Not a Feature.

In high-stress engineering, there is no room for doubt. When a component is subjected to immense torque, shock, and fatigue, 'strong enough' is not enough. It must be unquestionably resilient. SAE 4140 is the industry's answer to this challenge—a chromium-molybdenum alloy steel forged for the express purpose of withstanding forces that would shatter ordinary carbon steels.

The Benchmark for High-Tensile Performance

Withstand Extreme Forces

Delivers exceptional tensile and yield strength to handle heavy loads without deformation or failure.

Enhanced Resistance to Shock & Impact

The alloy composition provides superior toughness, allowing components to absorb sudden impacts without fracturing.

Achieve Deep, Uniform Hardness

Excellent hardenability allows for through-hardening in thick sections, ensuring consistent strength from surface to core.

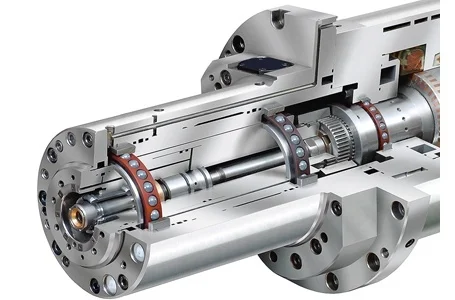

Outlast Cyclical Stress

High fatigue resistance makes it the ideal choice for rotating machinery and components under constant load cycles.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.38 - 0.43 |

| Manganese (Mn) | 0.75 - 1.00 |

| Chromium (Cr) | 0.80 - 1.10 |

| Molybdenum (Mo) | 0.15 - 0.25 |

| Phosphorus (P) | 0.035 Max |

| Sulphur (S) | 0.040 Max |

Mechanical Properties (Quenched and Tempered, indicative only)

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 850 - 1000 |

| Yield Strength (MPa) | ~680 |

| Hardness (Brinell) | 248 - 302 HB |

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| EN | EN19 / 42CrMo4 |

| W-Nr. | 1.7225 |

| JIS | SCM440 |

Similar & Alternative Grades:

SAE 4140 is a highly versatile chromoly steel, also known as DIN 42CrMo4 and JIS SCM440.

Frequently Asked Questions about SAE 4140

What is the difference between SAE 4140 and EN8D?

The primary difference is that SAE 4140 is an alloy steel, containing significant amounts of Chromium and Molybdenum. EN8D is a plain carbon steel. These alloying elements give 4140 vastly superior strength, toughness, and hardenability, making it suitable for much more demanding, high-stress applications.

Is SAE 4140 difficult to weld?

Yes, welding 4140 is challenging and requires careful procedure to avoid cracking. Due to its high hardenability, a comprehensive pre-heat (typically 200-300°C) and post-weld heat treatment (stress relieving) are essential for a successful weld.

What does "Quenched and Tempered" (Q&T) mean for 4140?

This is the standard heat treatment process that unlocks the high-strength properties of 4140. The steel is heated, rapidly cooled (quenched) in oil to achieve high hardness, and then reheated to a lower temperature (tempered) to reduce brittleness and achieve the final desired balance of strength and toughness.

A Promise Forged in Alloy

The integrity of your most critical machinery rests on the integrity of its smallest components. Choosing SAE 4140 is a declaration that you will not compromise on strength. The Marbrite Standard is our guarantee that the 4140 bright bar you receive has the precise alloy chemistry and flawless structure to deliver that strength—consistently and verifiably. Build with the material that was born for the pressure.