EN19 Alloy Steel (709M40)

The Proven Standard for High-Tensile Demands.

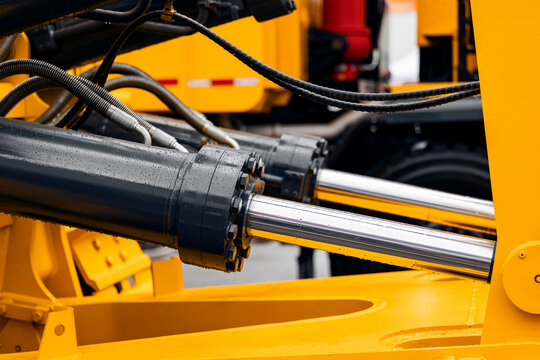

When an application demands more than just strength—when it requires a proven balance of toughness, shock resistance, and hardenability—engineers turn to EN19. This versatile chromium-molybdenum alloy steel bar has earned its reputation as the go-to material for critical, high-stress components across every sector, from automotive to industrial machinery. It is the benchmark for reliable performance under pressure.

The Benchmark for Versatile Strength

High Tensile Strength

Delivers the high-yield and tensile properties required for heavily loaded shafts, gears, and bolts.

Superior Material Toughness

Engineered to resist fracture from sudden impacts, making it ideal for critical, shock-loaded parts.

Good Through-Hardening

Its alloy chemistry allows for deep, uniform hardness, ensuring consistent strength in thicker sections.

A Versatile Performer

The trusted, all-around choice for a vast range of high-integrity automotive and engineering components.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.36 - 0.44 |

| Manganese (Mn) | 0.50 - 0.80 |

| Chromium (Cr) | 0.90 - 1.20 |

| Molybdenum (Mo) | 0.20 - 0.35 |

| Silicon (Si) | 0.10 - 0.35 |

Mechanical Properties (Hardened and Tempered 'T' Condition, indicative only)

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 850 - 1000 |

| Yield Strength (MPa) | ~695 |

| Hardness (Brinell) | 248 - 302 HB |

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| AISI / SAE | 4140 |

| BS 970:1991 | 709M40 |

| DIN / W-Nr. | 42CrMo4 / 1.7225 |

Similar & Alternative Grades:

EN19 is a versatile chromoly steel, also known as 709M40 and DIN 42CrMo4.

Frequently Asked Questions about EN19

Are EN19 and SAE 4140 the same steel?

Yes, for most practical purposes, EN19 and SAE 4140 are considered equivalent. They belong to different standards systems (British Standard and American) but have very similar chemical compositions and mechanical properties. They are often used interchangeably for high-tensile applications.

How does EN19 differ from EN24?

The main difference is that EN24 contains a significant amount of Nickel (around 1.5%). This addition of Nickel gives EN24 superior toughness and strength, especially in larger cross-sections. EN19 is a highly capable and more economical choice for a wide range of applications, while EN24 is reserved for the most extreme and critical demands.

What does the 'T' condition mean for an EN19 bright bar?

The 'T' condition signifies that the EN19 bright bar has been hardened and tempered to achieve its optimal high-tensile properties, typically a tensile strength of 850-1000 MPa. This is the most common condition in which EN19 is used for high-strength components.

A Benchmark of Integrity

Trust in an engineering component is not given; it is earned over years of flawless performance. EN19 has earned that trust. The Marbrite Standard is our guarantee that the EN19 cold drawn bar you receive is a perfect representation of this legacy, with a verified alloy chemistry and a defect-free structure. We deliver the benchmark material that allows you to engineer with the absolute certainty your critical applications demand.