EN24 Alloy Steel (817M40)

When There Is No Margin for Error.

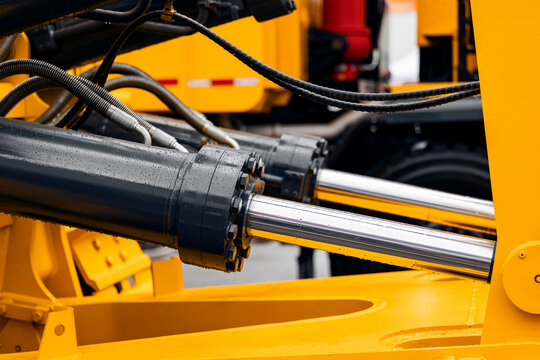

There are applications where high strength is not enough. Where the forces are so extreme, the shock loads so violent, and the consequences of failure so absolute, that only a superior class of steel will suffice. This is the domain of EN24. The addition of nickel to its chromium-molybdenum chemistry creates a high-tensile steel with exceptional toughness and fatigue resistance, making it the definitive choice for the most critical, heavily stressed components in modern engineering.

The Ultimate in High-Tensile Performance

Extreme Tensile Strength

Delivers exceptionally high tensile and yield strength, even in large cross-sections after heat treatment.

Superior Shock Resistance

The nickel content provides unparalleled toughness and ductility, resisting catastrophic fracture from sudden impacts.

Exceptional Fatigue Strength

Engineered to endure millions of high-stress load cycles, making it essential for high-performance rotating parts.

Excellent for Nitriding

Provides an ideal foundation for nitriding, creating a super-hard surface case for extreme wear resistance.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.36 - 0.44 |

| Nickel (Ni) | 1.30 - 1.80 |

| Chromium (Cr) | 0.90 - 1.40 |

| Molybdenum (Mo) | 0.20 - 0.35 |

| Manganese (Mn) | 0.45 - 0.70 |

Mechanical Properties (Hardened and Tempered 'T' Condition, indicative only)

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 850 - 1000 |

| Yield Strength (MPa) | ~680 |

| Hardness (Brinell) | 248 - 302 HB |

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| AISI / SAE | 4340 |

| BS 970:1991 | 817M40 |

| DIN / W-Nr. | 34CrNiMo6 / 1.6582 |

Similar & Alternative Grades:

EN24 is a superior nickel-chromoly steel, also known by its designations 817M40 and SAE 4340.

Frequently Asked Questions about EN24

What makes EN24 superior to EN19 / SAE 4140?

The key difference is the addition of approximately 1.5% Nickel. This significantly enhances EN24's toughness, impact strength, and ability to achieve deep, uniform hardness in larger sections. While EN19 is a superb all-around high-tensile steel, EN24 is the superior choice for the most critical, shock-loaded, and high-fatigue applications.

Is EN24 suitable for nitriding?

Yes, EN24 is an excellent steel for nitriding. This surface-hardening process can create an extremely hard, wear-resistant case (above 60 HRC) while the tough inner core remains unaffected, making it perfect for components like high-performance crankshafts and gears.

Can EN24 steel be welded?

Welding EN24 is extremely difficult and is not recommended for critical or structural applications. Its high alloy content makes it very prone to cracking. It requires highly specialized pre-heat, inter-pass, and post-weld heat treatment procedures and should only be considered as a last resort for minor repairs by an expert.

The Uncompromising Standard

When your design pushes the limits of engineering, the material it's built from must be beyond reproach. Choosing an EN24 bright bar is a decision to eliminate compromise. The Marbrite Standard is our guarantee that the material you receive is a perfect expression of this philosophy, with a verified nickel content and a flawless metallurgical structure. We deliver the absolute material integrity required for applications where the cost of failure is unthinkable.