EN18 Alloy Steel (5140)

The First Step Beyond Carbon Steel.

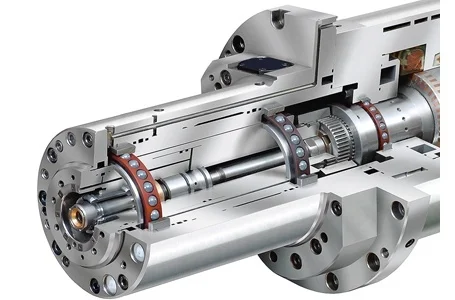

There comes a point where standard carbon steel is no longer enough. When operating stresses increase and a higher factor of safety is required, stepping up to an alloy steel is not a luxury—it's a necessity. EN18 is that first, crucial step. A versatile chromium steel, it provides a significant leap in strength and wear resistance, offering a new tier of reliability for components that have outgrown the limits of ordinary steel.

The Intelligent Upgrade

Increased Tensile Strength

The addition of chromium provides a significant boost in strength over medium-carbon steels like EN8D.

Superior

Wear Resistance

Harder and more durable than carbon steels, making it ideal for parts subjected to moderate wear.

Good Hardening Capability

Responds well to quenching and tempering to achieve a tough, high-strength final state.

An Economical Alloy

Choice

Offers the benefits of an alloy steel at an excellent price point for a wide range of applications.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.35 - 0.45 |

| Manganese (Mn) | 0.60 - 0.90 |

| Chromium (Cr) | 0.80 - 1.10 |

| Silicon (Si) | 0.10 - 0.35 |

| Phosphorus (P) | 0.040 Max |

| Sulphur (S) | 0.050 Max |

Mechanical Properties (Hardened and Tempered 'R' Condition, indicative only)

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 700 - 850 |

| Yield Strength (MPa) | ~520 |

| Hardness (Brinell) | 201 - 255 HB |

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| AISI / SAE | 5140 |

| DIN | 41Cr4 |

| W-Nr. | 1.7035 |

Similar & Alternative Grades:

EN18 is a versatile chromium steel, also known by its SAE designation 5140.

Frequently Asked Questions about EN18

What is the main difference between EN18 and EN8D?

EN18 is a chromium alloy steel, while EN8D is a plain carbon steel. The addition of chromium gives EN18 higher strength, better hardenability, and superior wear resistance compared to EN8D, making it suitable for more demanding applications.

How does EN18 compare to EN19 / SAE 4140?

EN19 (SAE 4140) is a chromium-molybdenum steel. The addition of molybdenum gives it significantly better toughness and hardenability, especially in larger cross-sections. EN18 is a more economical choice for components that require high strength but where the extreme toughness of EN19 is not necessary.

Is EN18 difficult to weld?

Yes, like most medium-carbon alloy steels, welding EN18 requires careful procedure. A pre-heat of 200-300°C and a post-weld stress relief treatment are highly recommended to prevent cracking and maintain its mechanical properties.

The Marbrite Standard for Your First Alloy

Making the move to an alloy steel is a commitment to a higher standard of performance. The Marbrite Standard for EN18 ensures that this step is a confident one. We provide EN18 bright bars with a verified chromium content and flawless structure, guaranteeing you receive the full mechanical benefits that an alloy steel promises. Don't just upgrade your material; upgrade your certainty.