EN31 Bearing Steel (100Cr6)

Where Endurance is Forged at a Microscopic Level.

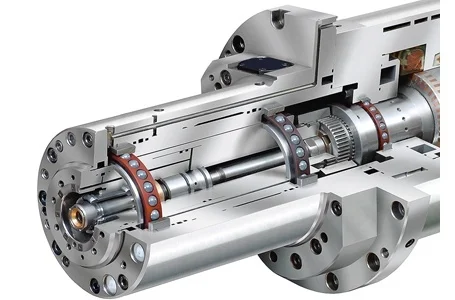

A bearing does not live an easy life. It endures millions of rotations under immense pressure, where the smallest microscopic imperfection can grow into a catastrophic failure. Endurance is not a feature; it is a science. EN31 is the embodiment of this science—a high-carbon, chromium alloy steel engineered for a single purpose: to provide a flawlessly clean and uniformly hard surface that can withstand the relentless punishment of rolling contact.

The Science of Longevity

Exceptional Surface Hardness

Through-hardens to an extremely high hardness (up to 64 HRC) for maximum resistance to deformation.

Ultimate Wear Resistance

The high carbon and chromium content creates a formidable defence against abrasive and adhesive wear.

High Fatigue Strength

Engineered with a clean microstructure to resist sub-surface fatigue over millions of load cycles.

Excellent Dimensional Stability

Maintains its precise shape and tolerances after heat treatment, which is critical for bearing applications.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.90 - 1.10 |

| Chromium (Cr) | 1.20 - 1.60 |

| Manganese (Mn) | 0.40 - 0.70 |

| Silicon (Si) | 0.10 - 0.35 |

Mechanical Properties (Hardened and Tempered, indicative only)

| Property | Value |

|---|---|

| Hardness | ~62 HRC |

| Tensile Strength (MPa) | ~2200 |

| Yield Strength (MPa) | ~1950 |

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| AISI / SAE | 52100 |

| DIN / W-Nr. | 100Cr6 / 1.3505 |

| JIS | SUJ2 |

Similar & Alternative Grades:

Also comparable to its German DIN equivalent 100Cr6 and the Japanese JIS standard SUJ2.

Frequently Asked Questions about EN31

Are EN31 and SAE 52100 the same?

Yes, they are generally considered to be the same grade of steel under different international standards. Both are high-carbon, chromium-based bearing steels with nearly identical chemistry and performance characteristics. They are used interchangeably in the industry.

Why is EN31 so good for bearings?

Its combination of very high carbon and chromium content allows it to be through-hardened to an exceptional hardness level (often over 60 HRC). This extreme hardness, combined with the material's inherent cleanliness and fine grain structure, provides the superior wear resistance and fatigue strength needed to withstand millions of rotations under load.

Can you machine an EN31 bright bar after it's hardened?

No. Once hardened, an EN31 bright bar is extremely difficult to machine with conventional tools. All machining, drilling, and shaping operations must be performed in the steel's soft, annealed state. After hardening, only grinding is a practical method for finishing.

The Science of a Longer Life

The lifespan of your machinery is determined by the lifespan of its most stressed components. For bearings and high-wear parts, that life is measured in revolutions and determined by the purity of the steel. The Marbrite Standard for EN31 is our commitment to providing a metallurgically clean, homogenous material. We deliver an EN31 round bar so free from the microscopic inclusions that seed failure, it provides the perfect, unblemished foundation for components that are not just built to run, but to endure.