EN353 Case Hardening Steel

Engineered for the Unforgiving Environment.

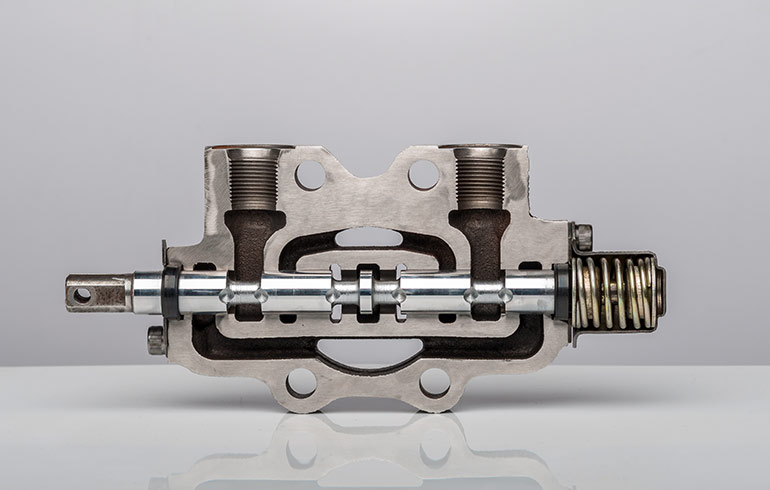

Standard components are built for standard conditions. But for heavy-duty machinery operating in the most unforgiving environments, 'standard' is a synonym for 'failure'. EN353 is engineered for this reality. It is a high-strength, nickel-chromium case hardening steel created to provide exceptional core toughness and strength, making it the definitive choice for gears, shafts, and transmissions that must endure the most severe shock loads and stresses.

The Standard for Heavy-Duty Resilience

Exceptional Core Strength

The high nickel content develops a remarkably strong and tough core after heat treatment.

Ultimate Impact Resistance

Engineered to absorb extreme shock loads and resist catastrophic fracture in heavy-duty applications.

High Surface Hardness

Achieves a hard, wear-resistant case (over 60 HRC) after carburizing to withstand intense friction.

The Heavy-Duty Standard

The proven material choice for commercial vehicle transmissions and critical industrial machinery.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.10 - 0.20 |

| Nickel (Ni) | 1.00 - 1.50 |

| Chromium (Cr) | 0.75 - 1.25 |

| Manganese (Mn) | 0.50 - 1.00 |

Mechanical Properties (Core properties after hardening, indicative only)

| Property | Value |

|---|---|

| Surface Hardness (Case) | Up to 62 HRC |

| Tensile Strength (Core) | 930 - 1230 MPa |

| Yield Strength (Core) | ~680 MPa |

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| BS | 655M13 |

| AISI / SAE | 3310 |

Similar & Alternative Grades:

EN353 is a high-nickel steel comparable to grades like EN36 for extreme-duty applications.

Frequently Asked Questions about EN353

What makes EN353 so much tougher than other case hardening steels?

Its high Nickel content of over 3% is the key. Nickel is a powerful alloying element that significantly increases the steel's core strength, toughness, and ability to absorb extreme shock loads without fracturing, making it far superior to grades like 8620 or 20MnCr5 in brutal conditions.

Is EN353 weldable?

Due to its low carbon content, an EN353 bright bar has fair weldability before case hardening. However, because of its high alloy content, it requires careful pre-heating and post-weld procedures to avoid cracking. Welding after the case has been hardened is not recommended.

The Heart of Heavy Industry

The reliability of your most powerful machinery is determined by the resilience of its core. The Marbrite Standard for EN353 is our commitment to providing a metallurgically sound foundation for your most demanding work. We deliver EN353 round bars with a verified alloy chemistry, ready to be transformed into components that don't just operate under pressure, but thrive on it. Build with the brute strength that heavy industry demands.