EN42 Carbon Spring Steel

The Unseen Force Holding It All Together.

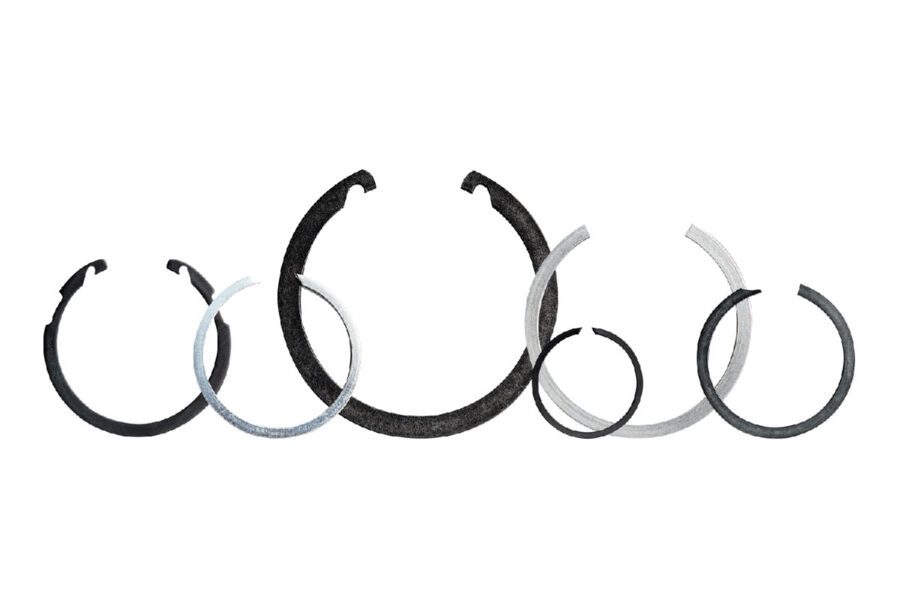

In every complex assembly, there are small, unseen components whose only job is to provide constant, reliable tension. A simple clip, a washer, a retaining ring—these are the parts that hold the modern world together. EN42 is the steel from which this reliability is forged. A high-carbon spring steel, it is engineered to be formed, hardened, and tempered into components that provide a lifetime of consistent, unwavering spring force.

The Art of Constant Tension

Good Elastic Properties

Can be heat-treated to achieve the excellent spring-back and elastic memory required for tensioning applications.

High Hardness & Strength

The high carbon content allows for a high hardness and tensile strength after treatment, ensuring it holds its form.

Excellent for Forming

Supplied in a soft, annealed state, it is ideal for stamping and forming complex shapes like washers and clips.

A Versatile Spring Material

The proven, economical choice for a wide array of general-purpose spring components and hand tools.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.75 - 0.85 |

| Manganese (Mn) | 0.60 - 0.90 |

| Silicon (Si) | 0.10 - 0.35 |

Mechanical Properties (Hardened and Tempered, indicative only)

| Property | Value |

|---|---|

| Hardness (Rockwell C) | 45 - 52 HRC |

| Tensile Strength (MPa) | ~1500 |

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| BS | CS80 |

| AISI / SAE | 1080 |

Similar & Alternative Grades:

SAE 9254 (for higher performance)Similar & Alternative Grades:

Also comparable to other high-carbon spring steels such as EN43 and SAE 1075.

Frequently Asked Questions about EN42

How is EN42 different from an alloy spring steel like SAE 9254?

EN42 is a plain **carbon spring steel**, deriving its spring properties from its high carbon content. SAE 9254 is an **alloy spring steel**, containing silicon and chromium. These additions give 9254 significantly higher performance, especially in fatigue life, making it suitable for dynamic, high-stress applications like vehicle suspension. EN42 is a more economical choice for general-purpose springs like washers and clips.

Can you weld EN42?

No. Due to its very high carbon content, welding EN42 is not recommended. It will become extremely brittle in the heat-affected zone and will be very prone to cracking. Furthermore, any welding will destroy the delicate spring properties achieved through heat treatment.

The Promise of Unwavering Tension

A component that loses its tension is a component that has failed. The Marbrite Standard for EN42 is our commitment to a consistent, verified carbon content that guarantees a predictable response to your heat treatment. We deliver **EN42 spring steel** that provides the reliable, lasting spring force your assemblies depend on. Build with the quiet confidence of a material designed to hold true.