16MnCr5 Case Hardening Steel

The European Standard for Resilient Gears.

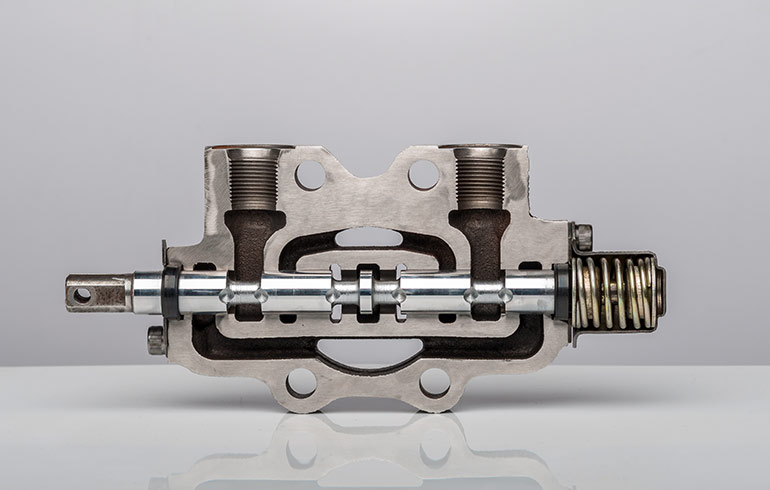

In the world of high-performance machinery, a gear is subjected to a lifetime of conflicting demands: a surface that defies wear and a core that absorbs shock. 16MnCr5 is the European standard engineered to resolve this conflict. A chromium-manganese case hardening steel, it is designed for a flawless and predictable response to heat treatment, creating the perfect synergy of a hard, wear-resistant case and a tough, ductile core.

The Synergy of Hardness and Toughness

Consistent Carburizing

Engineered for a uniform and predictable response to carburizing, ensuring reliable and consistent case depth.

High Surface Hardness

The carburized case can be hardened to over 60 HRC, providing exceptional resistance to abrasive wear.

Good Core Toughness

The low-carbon core remains ductile after treatment, providing the toughness to withstand shock and impact loads.

A Proven, Economical Grade

Offers an excellent balance of performance and value for a vast range of industrial and automotive components.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.14 - 0.19 |

| Manganese (Mn) | 1.00 - 1.30 |

| Chromium (Cr) | 0.80 - 1.10 |

| Silicon (Si) | 0.40 Max |

Mechanical Properties (Core properties after hardening, indicative only)

| Property | Value |

|---|---|

| Surface Hardness (Case) | ~62 HRC |

| Tensile Strength (Core) | 680 - 980 MPa |

| Yield Strength (Core) | ~490 MPa |

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| DIN / W-Nr. | 1.7131 |

| AISI / SAE | 5115, 5117 |

Similar & Alternative Grades:

Also comparable to its direct international equivalent, SAE 5115.

Frequently Asked Questions about 16MnCr5

What is the difference between 16MnCr5 and 20MnCr5?

They are very similar chrome-manganese case hardening steels. 20MnCr5 generally has slightly higher specified carbon and alloy content, which can result in slightly higher hardenability and core strength. The choice between them often depends on the specific OEM design specification and the required performance of the component.

How does 16MnCr5 compare to SAE 8620?

The main difference is that 8620 is a nickel-chromium-molybdenum alloy. The nickel content in 8620 provides superior core toughness and impact strength, making it the preferred choice for the most critical, high-shock applications. A 16MnCr5 bright bar is a highly effective and more economical solution for a vast range of demanding gear and shaft applications.

Is 16MnCr5 steel weldable?

Due to its low carbon content, 16MnCr5 has good weldability before any case hardening treatment. After the surface has been carburized and hardened, welding is not recommended as it will destroy the hard case and compromise the part's structural integrity.

The Engine of Your Production Line

Your production line relies on predictability. Your components rely on resilience. The Marbrite Standard for 16MnCr5 is our guarantee of a clean, consistent chemistry that provides a flawless response to your heat treatment processes. We deliver 16MnCr5 cold drawn bars that enable you to manufacture high-performance components at scale, with the confidence that comes from a perfectly reliable foundational material.