EN9 Carbon Steel (070M55)

For a Lifetime of Friction. And a Future Without Failure.

Some components are not designed for a quiet life. They are born into a world of abrasion, impact, and relentless wear. For these high-contact parts, a standard EN9 round bar is a countdown to failure. We deliver cold drawn bright bars with the verified integrity to dominate in the most punishing environments.

An Unyielding Standard of Hardness

Achieve Extreme Hardness

Responds exceptionally to flame and induction hardening, creating an intensely hard, wear-proof surface.

Dominate Abrasive Wear

The high carbon content provides a formidable defence against the grinding forces of friction and abrasion.

Maintain a Tough Core

Ideal for surface hardening, which creates a wear-resistant case while the core remains ductile to absorb impact.

Superior Edge Retention

Ideal for cutting tools, machine knives, and shear blades where holding a sharp, durable edge is critical.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.50 - 0.60 |

| Silicon (Si) | 0.05 - 0.35 |

| Manganese (Mn) | 0.50 - 0.80 |

| Sulphur (S) | 0.050 Max |

| Phosphorus (P) | 0.050 Max |

Mechanical Properties (in normalized condition, indicative only)

| Property | Value |

|---|---|

| Tensile Strength (MPa) | ~700 |

| Yield Strength (MPa) | ~355 |

| Hardness (Brinell) | ~201 HB |

Heat Treatment

| Normalizing | Heat to 820 - 850°C, cool in air. |

| Hardening | Heat to 820 - 850°C, quench in oil. |

| Tempering | Temper at 550 - 660°C to achieve desired toughness and strength. |

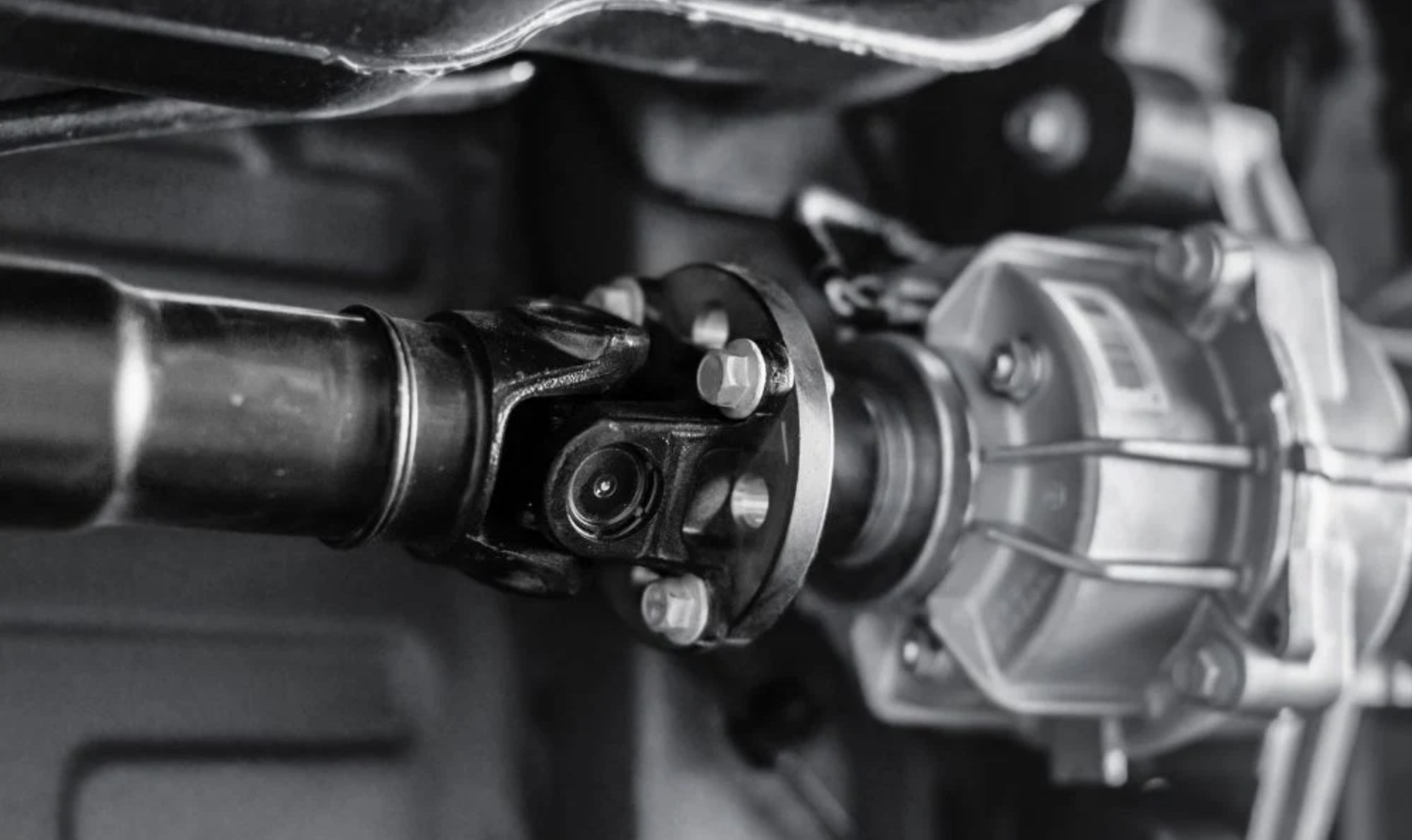

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| BS 970:1991 | 070M55 |

| AISI / SAE | 1055 |

| DIN | C55, CK55 |

| JIS | S55C |

Similar & Alternative Grades:

EN9 is a versatile high-carbon steel, also known by its SAE designation 1055, 50C8,C50.

Frequently Asked Questions about EN9

What is the main difference between EN9 and EN8D?

The primary difference is the higher carbon content in EN9 (0.50-0.60%) compared to EN8D (~0.40%). This makes EN9 significantly harder and more wear-resistant, but less tough and more challenging to weld. EN9 is chosen for surface durability (gears, cams), while EN8D is chosen for general strength and toughness (shafts, axles).

Is EN9 difficult to machine?

Machining EN9 is a craft that respects the material's inherent toughness. While its high carbon content presents a challenge compared to softer steels, the real enemy to your process is inconsistency. A predictably tough material can be planned for; a cheaper bar with hidden hard spots will shatter a tool and scrap a part without warning. We strongly recommend machining our homogenous EN9 in its annealed (softened) state to protect your tooling and achieve a flawless finish before its final hardening.

What is flame or induction hardening?

These are surface hardening techniques where only the outer layer of the steel is rapidly heated and then quenched. An EN9 bright bar is ideal for this process, as it creates an extremely hard, wear-resistant "case" (up to 55-60 HRC) while leaving the inner "core" of the material softer and tougher to absorb shock.

Can EN9 steel be welded?

Welding EN9 is highly challenging and generally not recommended for structural applications. Its high carbon content makes it extremely prone to cracking in the heat-affected zone. It requires specialized procedures, including very high pre-heat temperatures and controlled post-weld heat treatment, and should only be attempted by experienced professionals.

How does EN9 compare to a tool steel?

While EN9 is used for some cutting tools, true tool steels (like D2 or H13) are high-alloy steels with significantly more complex chemistry. Tool steels are engineered for extreme hardness, heat resistance, and abrasion resistance far beyond that of a plain carbon steel like EN9, and are used for the most demanding industrial tooling applications.

An Armour-Plated Promise

The gears in your machine are more than just parts; they are the teeth that drive your entire operation. A single weak tooth can shatter the whole system. The Marbrite Standard for EN9 is our commitment to providing a material with the metallurgical integrity to form a truly unyielding surface, an armour plating against the relentless forces of wear. Build with the confidence that your components are not just built to last, but built to prevail.