SAE 8620 Case Hardening Steel

The Blueprint for a Dual-Nature Component.

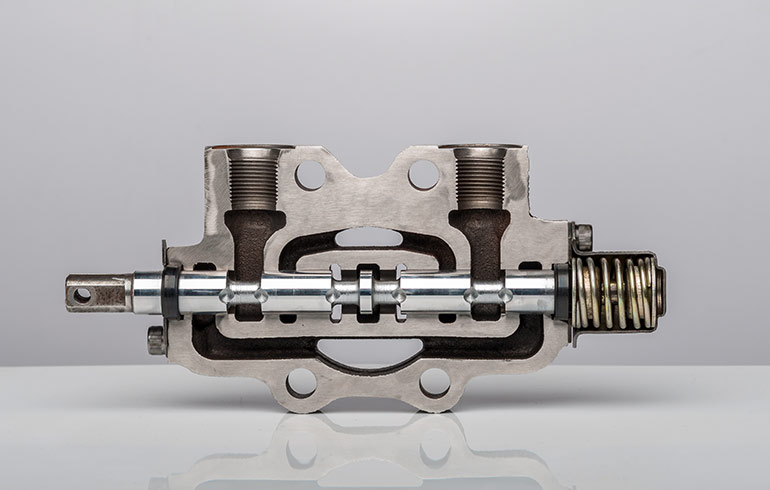

Some components live a double life. They must present a diamond-hard face to the world to defy wear, yet possess a soft, ductile heart to absorb the violence of shock and impact. This dual nature isn't a compromise; it's a sophisticated synergy. SAE 8620 is the blueprint for this synergy—a low-carbon alloy steel engineered for case hardening, allowing you to create components that are unbreakable on the outside and resilient on the inside.

The Synergy of Hardness and Toughness

Excellent Carburizing Response

Its low-carbon chemistry is designed to effectively absorb carbon, creating a hard, high-carbon surface case.

Achieve High Surface Hardness

The carburized case can be hardened to over 60 HRC, providing exceptional wear and abrasion resistance.

Maintain a Ductile Core

The low-carbon core remains unhardened, preserving its toughness and ductility to prevent fracture under shock loads.

Superior Core Strength

The alloy content (Nickel, Chromium, Molybdenum) gives the core good strength and fatigue resistance.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.18 - 0.23 |

| Manganese (Mn) | 0.70 - 0.90 |

| Nickel (Ni) | 0.40 - 0.70 |

| Chromium (Cr) | 0.40 - 0.60 |

| Molybdenum (Mo) | 0.15 - 0.25 |

Mechanical Properties (Core properties after hardening, indicative only)

| Property | Value |

|---|---|

| Surface Hardness (Case) | ~62 HRC |

| Tensile Strength (Core) | 800 - 1100 MPa |

| Yield Strength (Core) | ~650 MPa |

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| DIN / W-Nr. | 21NiCrMo2 / 1.6523 |

| JIS | SNCM220 |

| BS | 805M20 |

Similar & Alternative Grades:

Also comparable to its British Standard equivalent 805M20 and the Japanese JIS standard SCM420.

Frequently Asked Questions about SAE 8620

What does "Case Hardening" mean for 8620?

Case hardening is a process where carbon is infused into the surface of a low-carbon steel like an 8620 round bar. When the part is then quenched, only the high-carbon "case" becomes extremely hard, while the low-carbon "core" remains soft and tough. This creates a component with the best of both worlds.

How does 8620 compare to 20MnCr5?

Both are excellent case hardening steels. The main difference is that 8620 is a nickel-chromium-molybdenum steel, while 20MnCr5 is a chrome-manganese steel. The nickel content in 8620 generally provides superior core toughness and impact strength, making it the preferred choice for more critical, high-shock applications.

Can SAE 8620 be welded?

Yes, due to its low carbon content, 8620 has good weldability in its as-supplied, un-carburized state. However, welding after the case hardening treatment is not recommended, as it will destroy the hardened case and compromise the part's integrity.

The Integrity of Two Steels in One

A component is only as strong as its weakest point—be it a surface that wears too soon or a core that shatters on impact. The Marbrite Standard for SAE 8620 is our commitment to a flawless chemical foundation. We provide 8620 bright bars with the precise alloy balance to ensure a consistent, predictable response to carburizing, giving you the power to create a component with the dual nature you demand: an impenetrable case and an unbreakable core.