EN1A & EN1AL Free-Cutting Steel

The Fuel for High-Velocity Manufacturing.

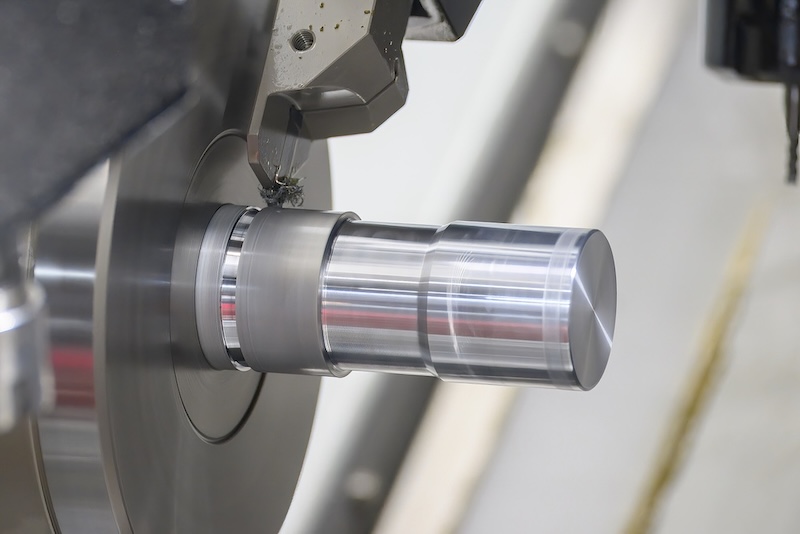

Modern manufacturing is a race against time. The ultimate goal is a flawless component, produced in the shortest possible cycle, with minimal tool wear. This is a challenge that cannot be met with ordinary steel. EN1A and its leaded variant, EN1AL, are the solution—specialized free-cutting steels designed not just to be machined, but to be devoured by modern, high-speed lathes, ensuring a rapid, fluid, and profitable production process.

The Chemistry of Efficiency

Extreme Machinability

Engineered to produce short, brittle chips that break cleanly, allowing for the highest possible cutting speeds.

Flawless Surface Finish

The free-cutting action results in a superior surface finish directly off the machine, reducing secondary operations.

EN1A: The Industry Standard

The proven, non-leaded choice for a vast range of high-volume, precision-machined components.

EN1AL: The Ultimate Accelerator

The addition of lead provides self-lubricating properties for the absolute maximum machining speeds and tool life.

Technical Specifications

Chemical Composition

| Element | EN1A (%) | EN1AL (Leaded) (%) |

|---|---|---|

| Carbon (C) | 0.07 - 0.15 | 0.07 - 0.15 |

| Manganese (Mn) | 0.80 - 1.20 | 0.80 - 1.20 |

| Sulphur (S) | 0.25 - 0.35 | 0.25 - 0.35 |

| Lead (Pb) | - | 0.15 - 0.35 |

| Phosphorus (P) | 0.07 Max | 0.07 Max |

Common Applications

Equivalent International Grades

| Standard | Grade (for EN1A) |

|---|---|

| BS 970 | 230M07 |

| AISI / SAE | 1213, 1215 |

| DIN / W-Nr. | 9SMn28 / 1.0715 |

Similar & Alternative Grades:

Also comparable to other international grades such as DIN 9SMn28 and SAE 1215.

Frequently Asked Questions about EN1A / EN1AL

What is the main difference between EN1A and EN1AL?

The 'L' in EN1AL stands for Lead. EN1AL contains a small, controlled addition of lead, which acts as an internal lubricant and chip breaker. This gives it even higher machinability than standard EN1A, making it the superior choice for the fastest and most demanding production rates on automatic lathes.

What does "free-cutting" mean?

Free-cutting steel is engineered with elements like Sulphur (in EN1A) and Lead (in EN1AL) that form soft inclusions within the material. During machining, these inclusions act as stress points, causing the metal chips to break off into small, manageable pieces. This dramatically reduces friction, tool wear, and heat, allowing for much faster and cleaner machining.

Can you weld or heat-treat EN1A?

No. EN1A and EN1AL are not designed for strength or fabrication. The high sulphur and lead content make them unsuitable for welding, as it will result in porous and cracked welds. Similarly, their low carbon content means they cannot be meaningfully hardened through heat treatment.

Unlock Your Machine's Potential

Your investment in high-speed machinery is only as good as the material you feed it. The Marbrite Standard is our commitment to providing a perfectly consistent free-cutting steel. We deliver EN1A and EN1AL bright bars that liberate your equipment to run at the speeds it was designed for, transforming your production line from a process into a fluid, high-velocity stream of perfect components.