Case Hardening Steels

The Synergy of a Hard Surface and a Tough Core.

A gear with a brittle core is a promise of catastrophic failure. It is the difference between a machine that performs, and one that shatters—taking your reputation with it. Our case hardening steels provide the crucial synergy that ensures resilience from the inside out.

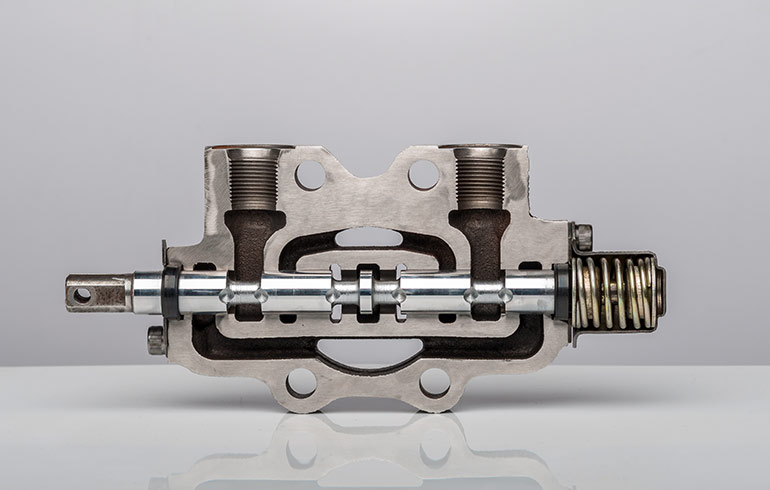

The Soul of a Gear

A gear is the heart of a machine, but a gear with a brittle core is a promise of catastrophic failure. It is an engineering paradox: to create a component that is diamond-hard on its surface to defy wear, yet resilient at its core to absorb the violence of impact. This delicate, crucial synergy is not an accident; it is a discipline. It is the difference between a machine that performs, and one that shatters—taking your reputation with it.

Achieve Consistent Case Depth

Our clean chemistry ensures a predictable and uniform response to carburizing and heat treatment.

Prevent Brittle Fracture

Engineered to produce a tough, ductile core that absorbs shock and impact without failing.

Superior Wear Resistance

Creates a diamond-hard surface case that provides exceptional resistance to abrasion and wear.

Ensure Predictable Treatment

The metallurgical purity of our steel guarantees reliable and repeatable results in your workshop.

Select a Grade for Detailed Specifications

Real-World Applications

A Process Forged on Principle

While others chase surface hardness, we engineer the crucial synergy between a wear-resistant case and a shock-absorbing core. The Marbrite Standard is our commitment to metallurgical purity, ensuring a clean chemistry that allows for a predictable, uniform transformation during heat treatment. This is the difference between a component that merely functions, and one whose resilience you can build a reputation on.