20MnCr5 Case Hardening Steel

The Workhorse of Modern Gear Manufacturing.

In the high-volume world of automotive and industrial manufacturing, performance must be predictable. A single batch of inconsistent steel can derail a production schedule and compromise thousands of components. 20MnCr5 is the industry's trusted solution for this challenge—a chrome-manganese case hardening steel engineered for a consistent, reliable response to heat treatment, delivering the perfect synergy of a wear-resistant case and a tough core, every single time.

The Standard for Production at Scale

Consistent Carburizing

Engineered for a uniform and predictable response to carburizing, ensuring consistent case depth across batches.

High Surface Hardness

The carburized case hardens to over 60 HRC, providing excellent resistance to wear and abrasion.

Good Core Toughness

The low-carbon core remains ductile after treatment, providing the toughness to withstand shock loading.

An Economical, Proven Grade

Offers a highly effective and economical solution for a vast range of high-volume automotive components.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.17 - 0.22 |

| Manganese (Mn) | 1.10 - 1.40 |

| Chromium (Cr) | 1.00 - 1.30 |

| Silicon (Si) | 0.40 Max |

Mechanical Properties (Core properties after hardening, indicative only)

| Property | Value |

|---|---|

| Surface Hardness (Case) | ~62 HRC |

| Tensile Strength (Core) | 780 - 1080 MPa |

| Yield Strength (Core) | ~590 MPa |

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| DIN / W-Nr. | 16MnCr5 / 1.7131 |

| SAE | 5120 |

| BS | 590H17 |

Similar & Alternative Grades:

Also comparable to international grades such as SAE 5120 and BS 590H17.

Frequently Asked Questions about 20MnCr5

What is 20MnCr5 primarily used for?

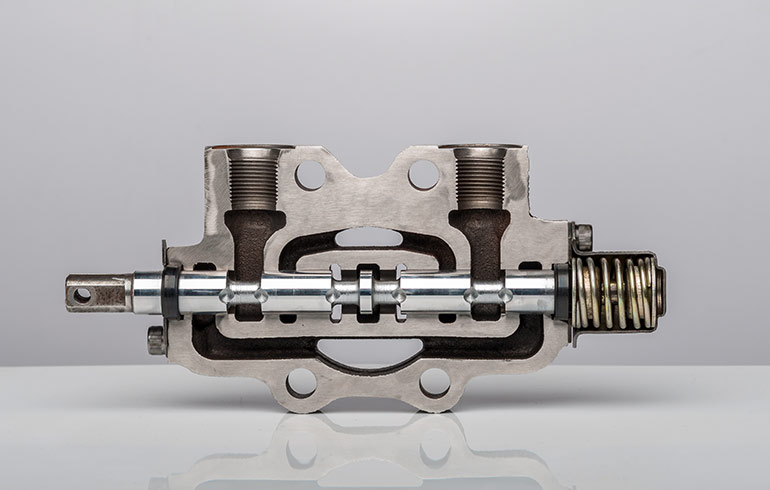

It is one of the most popular steels for the automotive industry, widely used to manufacture high-volume case hardened components like gears, pinions, camshafts, and transmission shafts where excellent surface wear resistance and good core toughness are required.

How does 20MnCr5 compare to SAE 8620?

Both are superb case hardening steels. The main difference is that 8620 is a nickel-chromium-molybdenum alloy, while 20MnCr5 is a chrome-manganese alloy. The nickel in 8620 provides superior core toughness and impact strength, making it ideal for the most critical shock loads. 20MnCr5 is a more economical solution that offers excellent performance for a vast range of automotive and industrial parts.

What is the correct case depth for a 20MnCr5 bright bar?

The required case depth is not a property of the 20MnCr5 bright bar itself, but is determined by the component's design requirements. The final case depth is a result of the carburizing process—specifically the time, temperature, and atmosphere—which can be precisely controlled to meet your specific engineering needs.

The Engine of Your Production Line

Your production line relies on predictability. Your components rely on resilience. The Marbrite Standard for 20MnCr5 is our guarantee of a clean, consistent chemistry that provides a flawless response to your heat treatment processes. We deliver 20MnCr5 cold drawn bars that enable you to manufacture high-performance components at scale, with the confidence that comes from a perfectly reliable foundational material.