EN8D Carbon Steel (080M40)

The Grade You Know. The Integrity You Demand.

The greatest risks in engineering are the ones you can't see. A hidden flaw, an inconsistent chemistry—these are the ghosts that haunt a production line, hiding inside what looks like a standard EN8D round bar. Our obsession is to exorcise these ghosts, delivering cold drawn bright bars with such verifiable integrity that the performance you expect is the only performance possible.

The Marbrite Standard for a Standard Grade

A Flawless Chemical Blueprint

Because the MTC isn't just a document; it's a promise. A promise that the steel's fundamental character is pure, ensuring its integrity remains absolute from the first cut to the final hardening.

Strength Without Brittleness

The ideal balance of properties, providing superior strength over mild steel while retaining the toughness to resist fracture.

Achieve Predictable Hardness

Our verified chemistry ensures a reliable and uniform response to heat treatment, batch after batch.

The Smart, Reliable Foundation

A proven, cost-effective foundation for your components, fortified by a standard of quality you can trust.

Technical Specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.40 - 0.45 |

| Silicon (Si) | 0.10 - 0.40 |

| Manganese (Mn) | 0.70 - 0.90 |

| Sulphur (S) | 0.050 Max |

| Phosphorus (P) | 0.050 Max |

Mechanical Properties (indicative)

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 550 - 700 |

| Yield Strength (MPa) | >210 |

| Hardness (Brinell) | 150 - 210 HB |

Heat Treatment

| Normalizing | Heat to 830 - 860°C, cool in air. |

| Hardening | Heat to 830 - 860°C, quench in oil or water. |

| Tempering | Temper at 550 - 660°C to achieve desired mechanical properties (e.g., Condition 'T'). |

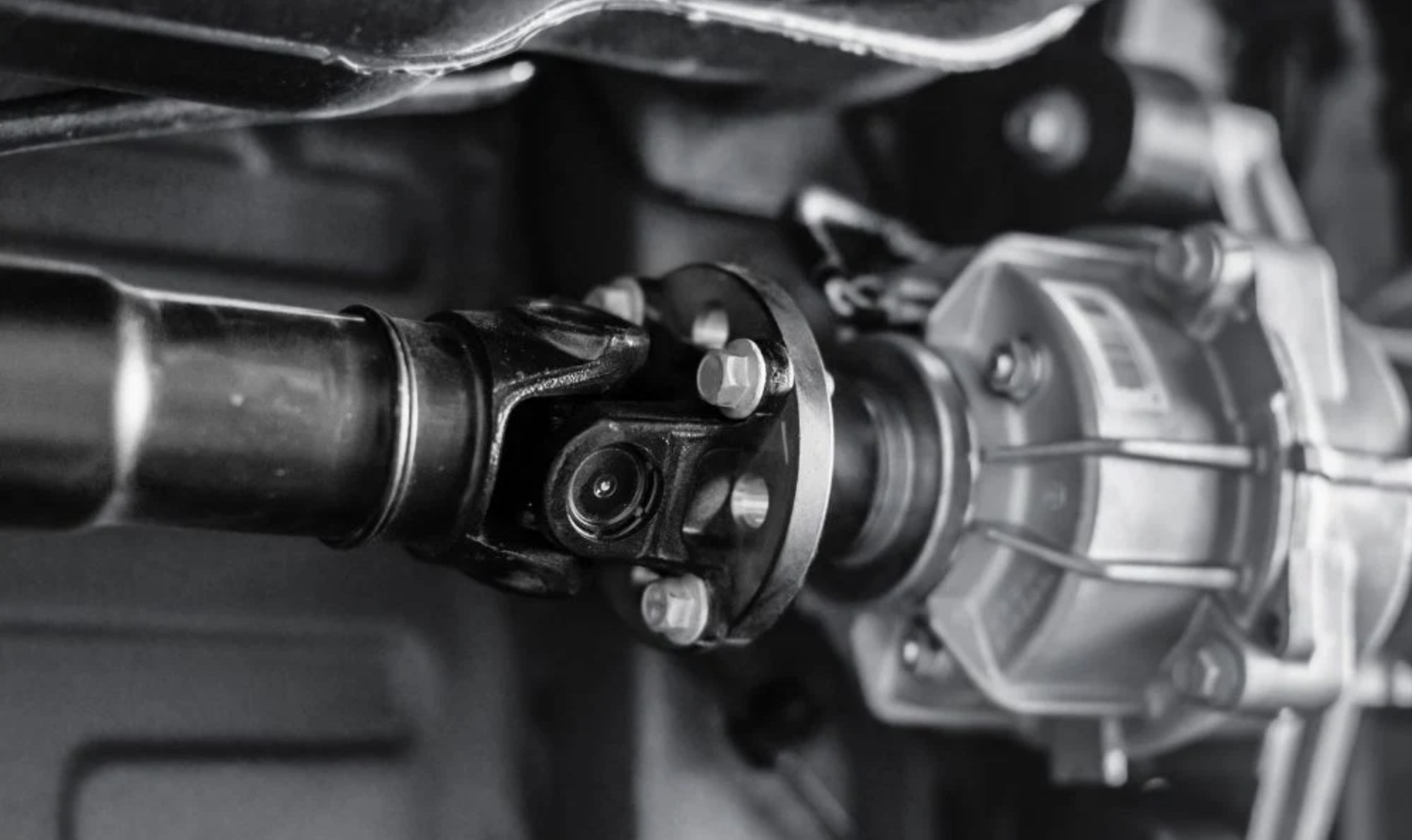

Common Applications

Equivalent International Grades

| Standard | Grade |

|---|---|

| BS 970:1991 | 080M40 |

| AISI / SAE | 1040, 1045 |

| DIN | C40, CK40, C45 |

| JIS | S40C, S45C |

Similar & Alternative Grades:

EN8D is a highly versatile carbon steel, also known by 080A40 and 45C8.

Frequently Asked Questions about EN8D

What is the difference between EN8 and EN8D?

The primary difference is in the chemistry, which is critical for producing high-quality EN8D bright bars. EN8D is a specific selection within the EN8 grade that is controlled to have a higher carbon content (typically 0.40-0.45%), which guarantees superior and more consistent hardenability.

Strength vs. Weldability: EN8D vs. EN8M vs. Mild Steel?

Mild Steel has the lowest carbon, making it easy to weld but providing the lowest strength.

EN8D, typically supplied as a cold drawn round bar, has a higher carbon content for significantly greater strength and hardenability, but this requires proper welding procedures.

EN8M is a specialized variant best known for its superior machinability. For a balance of strength and weldability, engineers typically select a steel with carbon content controlled on the lower end of the specification.

What hardness can EN8D achieve?

In its untreated state as a bright bar, the hardness is typically low (less than 20 HRC). After being heated and rapidly cooled, an EN8D round bar can reach its peak hardness of up to 45 HRC (oil quenching) or 55 HRC (water quenching), making it ideal for hardening applications.

How is EN8D better than Mild Steel?

An EN8D round bar is significantly superior to Mild Steel due to its higher carbon content. It offers substantially higher tensile strength and wear resistance and is designed for heat treatment, making it suitable for high-performance components where mild steel would fail.

How is the machinability of an EN8D bright bar?

In its cold drawn condition, an EN8D bright bar offers excellent machinability. Our EN8D provides a superior and consistent machining experience compared to standard grades, protecting tool life. After hardening, the material typically requires grinding.

A Foundation Worthy of Your Craft

Your expertise is in the thousand details of a perfect process. Our obsession is in the one detail that makes it all possible: a metallurgically flawless foundation. We provide more than just EN8D that is 'in-spec'; we deliver a material so clean and consistent that it liberates your process, allowing your craftsmanship to achieve its truest expression, free from the doubt of a flawed beginning.